What is an ERP?

All company areas like finance, human resources, sales, or manufacturing are impacted by implementing an Enterprise Resource Planning (ERP) system.

Your business should be well prepared with discussions with external stakeholders before and after the implementation to ensure a smooth transition. This entire process requires a full transfer of all your current data into a brand-new system making it a time-consuming yet rewarding process. Wish to read more about ERP and its implementation? Read here.

Given the multiple procedures that must take place every day just to keep a facility operating, ERP is a natural fit for the manufacturing industry. The following are some examples of processes that ERP may assist manage and streamline; take note of the various ways that these processes can now “speak” to each other via ERP, a major advantage that will be covered in more detail below.

Manufacturing – Maintenance + Product Lifecycle Management (PLM) + Quality

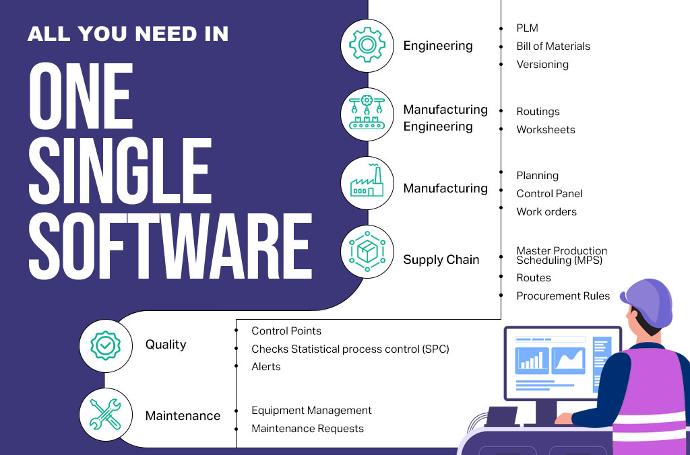

Enhance your supply chain and production procedures with these factory management apps from Odoo while also improving overall business productivity. You can manage all of your product data in one system thanks to their complete integration with all other Odoo Apps. Optimize your inventory levels by automating your purchases using made-to-order rules, minimum stock rules, or the master production schedule.

Why do you need the Work center Control Panel?

1. Amazing reporting and KPIs

Control your output by keeping an eye on the 6 major Total Productive Maintenance (TPM) losses with real-time Overall Equipment Efficiency (OEE) statistics. Monitor KPIs for maintenance such as Mean time before failure (MTBF) and Mean time to restore (MTTR). Adaptive dashboards can be made to track performance in real-time.

2. Improve the level of your inventory by using precise fulfillment propositions.

To automate procurements, use the master production schedule, minimum stock rules, or make-to-order rules. Allow the scheduler to perform all computations. Use routes, limitations, and lead time to maximize inventory level and prevent shortages.

3. Full integration for maximum benefit – take advantage of other Odoo Apps

Use Purchase to automatically fulfill and maintain correct inventory levels. You can easily manage PLM to manage engineering changes and versions easily. PLM will help you manage engineering changes and versions easily. Plan preventive maintenance and act quickly to correct problems. Combine multiple applications provided by the same service platform to easily maximize and define quality control points and trigger quality alerts.

Experience Odoo Manufacturing for yourself.

Get your FREE QUOTE and Book your free Odoo Demo with us today!

Contact us here